Engineering a Safer World

We provide leading engineering consulting, testing and training services across Australia.

Our expertise covers an expansive array of disciplines including Materials Engineering, Asset Condition Monitoring, Floor Consulting and Expert Witness Services.

ATTAR Unveils World Class Facilities and Boosts investment in WA

Click the link/image below to read the full article

Engineering Consulting

Services

Why Choose ATTAR?

Experience

ATTAR has been providing Australia and the world with expertise in Compliance, Engineering, Condition Monitoring and NDT Training for over 30 years.

Quality

ATTAR prides itself on providing world class services and solutions, both locally in Australia and internationally. We are innovators in our fields.

Customer

Our consultants, trainers and engineers put the customer first and work to form strong partnerships with our clients.

Occupational Exposure to Black Light in NDT

Occupational Exposure to Black Lights in NDT The Occupational standard for exposure to ultraviolet radiation

Causes of Fire on Heavy Vehicles

Heavy vehicles like trucks, trailers and busses are important company assets and represent a great loss if fire incidents occur. Loss of a vehicle is also traumatic for the driver.

The Changing Face of NDT Training

The Changing Face of NDT Training It is vital for any industry to continually develop

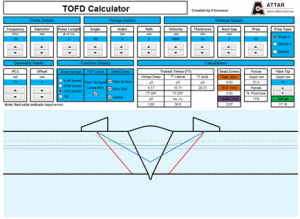

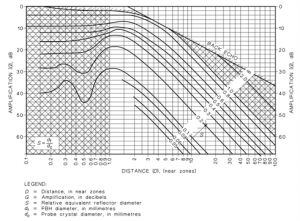

Discontinuity Sizing: Reflectivity Curves and Distance Gain Size (DGS)

Reflectivity Curves and Distance Gain Size (DGS) for Discontinuity Sizing The use of Reflectivity Curves

Trusted by Companies Across Australia

Looking for a Professional Writing Course?

Our online professional writing course covers a range of writing styles, grammar, reasoning skills, and the function of language to improve your technical report writing.